Faceplates and Overlays

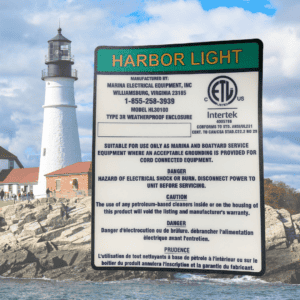

Labels hold immense significance in packaging, serving as a conduit of vital product information like its identity, components, and expiry date. However, not all labels can weather harsh conditions such as extreme temperatures, aggressive chemicals, and severe weather. At PPS, we specialize in crafting labels catered to the aviation, aerospace, and nautical sectors, ensuring resilience in demanding environments.

Among the labels tailored for rugged conditions, we offer high-temperature labels composed of flame-retardant polycarbonate. These labels remain unfazed by soaring temperatures, evading melting, fading, or deterioration. Widely employed for nameplates, faceplates, logos, cautionary labels, and operational panels in the automotive, aerospace, and manufacturing domains. PPS also extends chemical-resistant labels constructed from materials that withstand brutal chemicals and solvents sans disintegration or fading. These labels are a staple in chemical, petroleum, pharmaceutical, and laboratory industries.

Beyond material composition, the printing technique is pivotal for labels built to brave extreme conditions.

Conventional methods may fall short, warranting digital printing avenues like inkjet or thermal transfer. These methods yield high-quality prints impervious to fading and deterioration. PPS prides itself on an elite digital printing lineup, housing 4 HP Indigo printers and a Swiss Q Impala, exemplifying the apex of digital printing.

In the world of digitally printed labels, being able to withstand tough conditions is a must-have. These special labels are crucial for products tested in challenging environments. Companies use PPS labels to make sure their products display the right information clearly, even in the toughest situations.